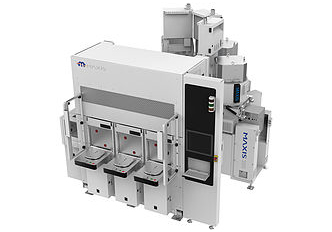

DRIE Etcher

Overview

Our DRIE(Deep Reactive Ion Etching) Etcher conducts fine cycling & non-cycling etching process of silicon substrate by utilizing high-density plasma. It is applicable for various etching process such as deep trench, isotropic profile with its high-speed etching capability and high aspect ratio.

This machine is cluster type(up to chambers) and suitable for mass production line that fabricate 4"~8" wafer.

Industry Opportunity

- • Increase in DRIE-applicable fabricating & packaging processes in semiconductor industry that were limited to MEMS device

- • DRIE-applicable processes for 3D TSV, 2.5D interposer, PMIC, CIS and other analog devices arose due to 'Micro to Macro' trend in semiconductor industry

- • Expansion of applicable field beyond silicon substrate such as polyimide, Quartz, SiC and so on

Core Competency

- • Superior process capability : cycling & non-cycling, high-speed etching, process uniformity, and high aspect ratio with profile control, smooth surface, egde profile control, edge shadow ring

- • Wide process window : Micro to Macro, MEMS to Semiconductor

- • Providing customized DRIE etcher that is optimized for customer's product and process features by utilizing our own demo laboratory

Application

- • Through silicon via

- • Deep trench isolation

- • Blanket etch

- • Tapered etch

- • High aspect ratio

- • Smooth sidewall

- • In-situ process

- • 3D IC

- • MEMS

- • Power device